Plant cleaning & hygiene

WAPOTEC® Plant Hygiene and Cleaning Solutions

- Protect Patrons

- Improve Water and Air quality

- Save Cost

- Avoid Shutdown/(Forced) Closure

- Protect your Investment (Equipment & Infrastructure)

Why is preventative maintenance important and often ignored?

Preventative maintenance of water treatment plants is often undervalued because most components are hidden and generally not easily accessible. However, the cost of ignoring can become substantial when an outbreak hits the facility.

Once a facility is infested, a quick and effective intervention is required. (see WAPOTEC® solutions offered)

What areas are affected?

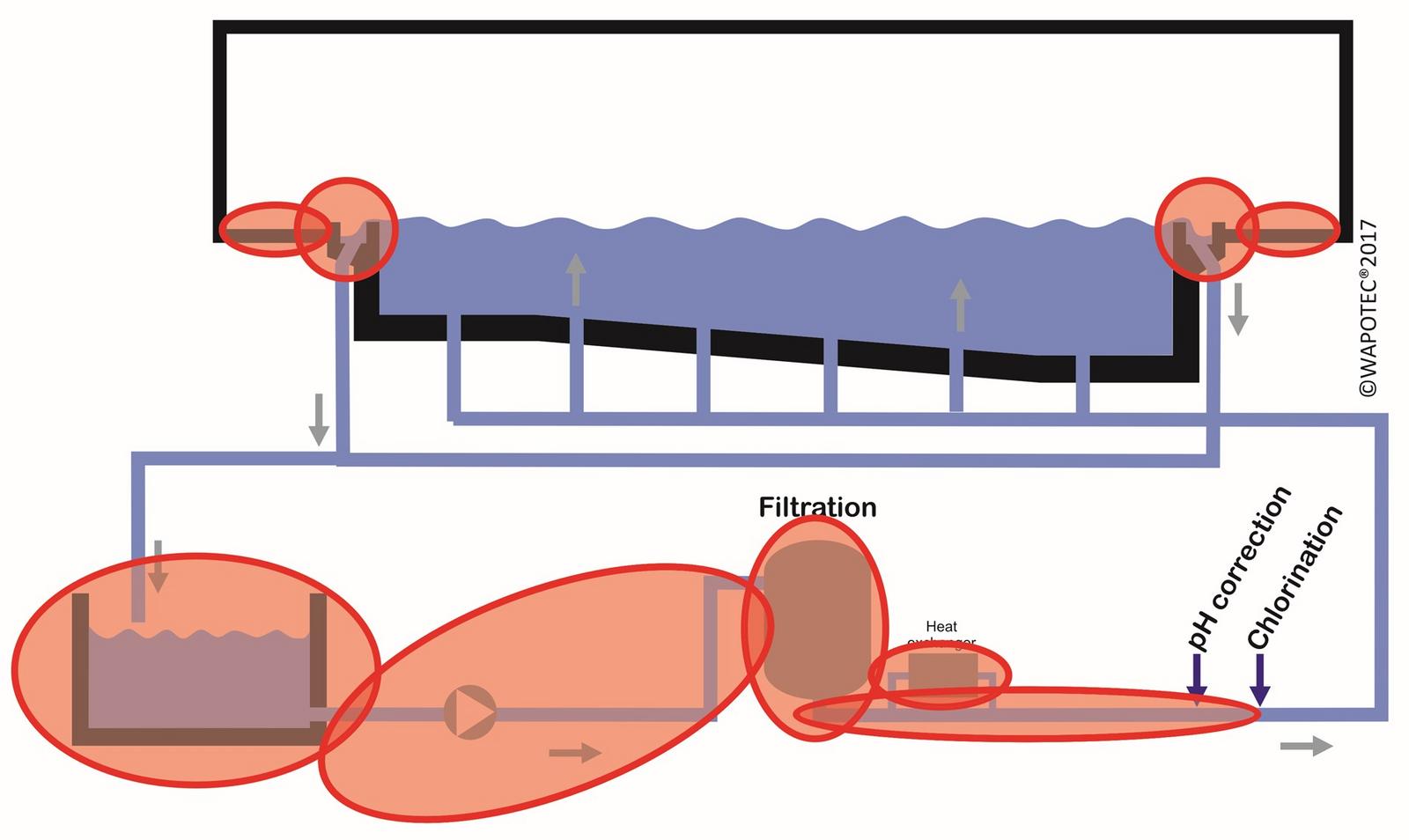

The following graph highlights the most important areas to look at:

Why installations become affected?

When wetted parts are exposed to contaminants, deposits can be created and microorganisms can proliferate on deck and plant surfaces. Regular removal of such deposits and/or disinfection of microorganisms is therefore an essential and integral part of the overall preventative maintenance and plant hygiene but it also helps to

- minimize operating cost,

- offer sustainable benefits and

- avoid adverse effects on the water treatment efficacy and the water quality.

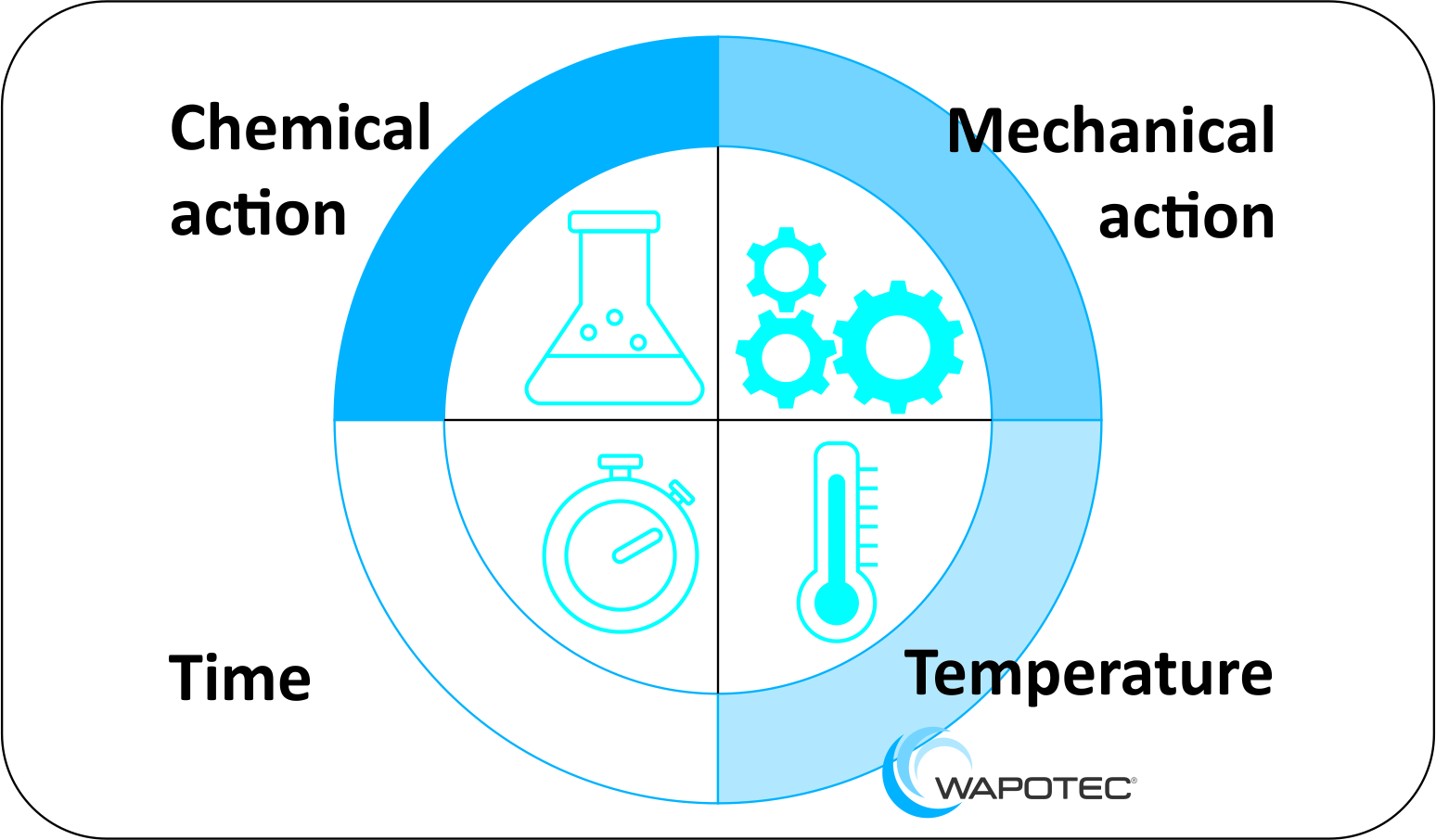

All efficient cleaning processes require a balance between 4 principle factors (see image).

Chemical action refers to the cleaning product and its concentration, while mechanical action means dissolving of deposits both manually as well as by physical contact of the cleaning solution with the surface to be cleaned. All of that has to best done at a certain temperature and over a certain contact time as expressed by the Sinner circle.

Efficacies in disinfection of microorganisms are measured by adequate CT factor (concentration [mg/l] x time [min]).

What solutions does WAPOTEC offer?

WAPOTEC® and other members of the WAPOTEC®Group have researched and developed solutions that can optimize requirements and provide a better process-control in (preventative) cleaning and disinfection processes. Applicability and customization options have resulted in process technologies which are mostly patented internationally.

WAPOTEC® remediation strategies are developed to intervene in case of incidences or general plant contamination, such as

- Liquid fecal incidents caused by cryptosporidium infected patrons

- Legionella -contaminated or pseudomonas-infested spas and pool attractions

WAPOTEC® offers a wide range of outstanding and unique solutions, including

- Filter Media Cleaning and Remediation

- Regeneration of activated carbon inside the filter tank

- Crypto (Cryptosporidium parvum) Removal & Remediation of swimming pool water

- Cleaning & Remediation for Whirlpools & SPA

- Surface cleaning and disinfection (swim toys, pool vacuum cleaners/robots)

- Deck cleaning and plant hygiene (deck, scum channel, balance tanks and heat exchangers)

The following summarizes some of the technologies offered:

Surface cleaning and disinfection (swim toys, pool vacs)

Traditional disinfecting agents and cleaners need to be thoroughly rinsed from different surfaces – meaning a labor intensive and costly exercise. Cleaning solutions often find their way into the pool water, causing problems for the filtration and disinfection equipment, creating undesirable disinfection by-products responsible for odor, irritation and even corrosion.

DesoPur®F not only distinguishes itself through its effectivity against biofilm, but is also compatible with water disinfectants (chlorination) because it does not contain any water quality-impairing additives. It is well known for its effectiveness in degrading and removing biofilms, Pseudomonas and Legionellae and does not need to be rinsed off so that treated surfaces are safe for use only minutes after application.

Deck cleaning and hygiene (deck, scum/overflow channel, skimmers and balance tanks)

Pool decks and change room areas should be treated regularly with DesoZid®F to break biofilm and limit the proliferation of pathogens, such as Pseudomonas to the pool deck areas.

DesoPur® Filter Media Cleaning, Remediation and Regeneration

Filter media often becomes contaminated over time which is usually detected after testing the filtrate (i.e. water after the filter). is often found to be microbiologically objectionable which means a significant risk with regards to water hygiene.

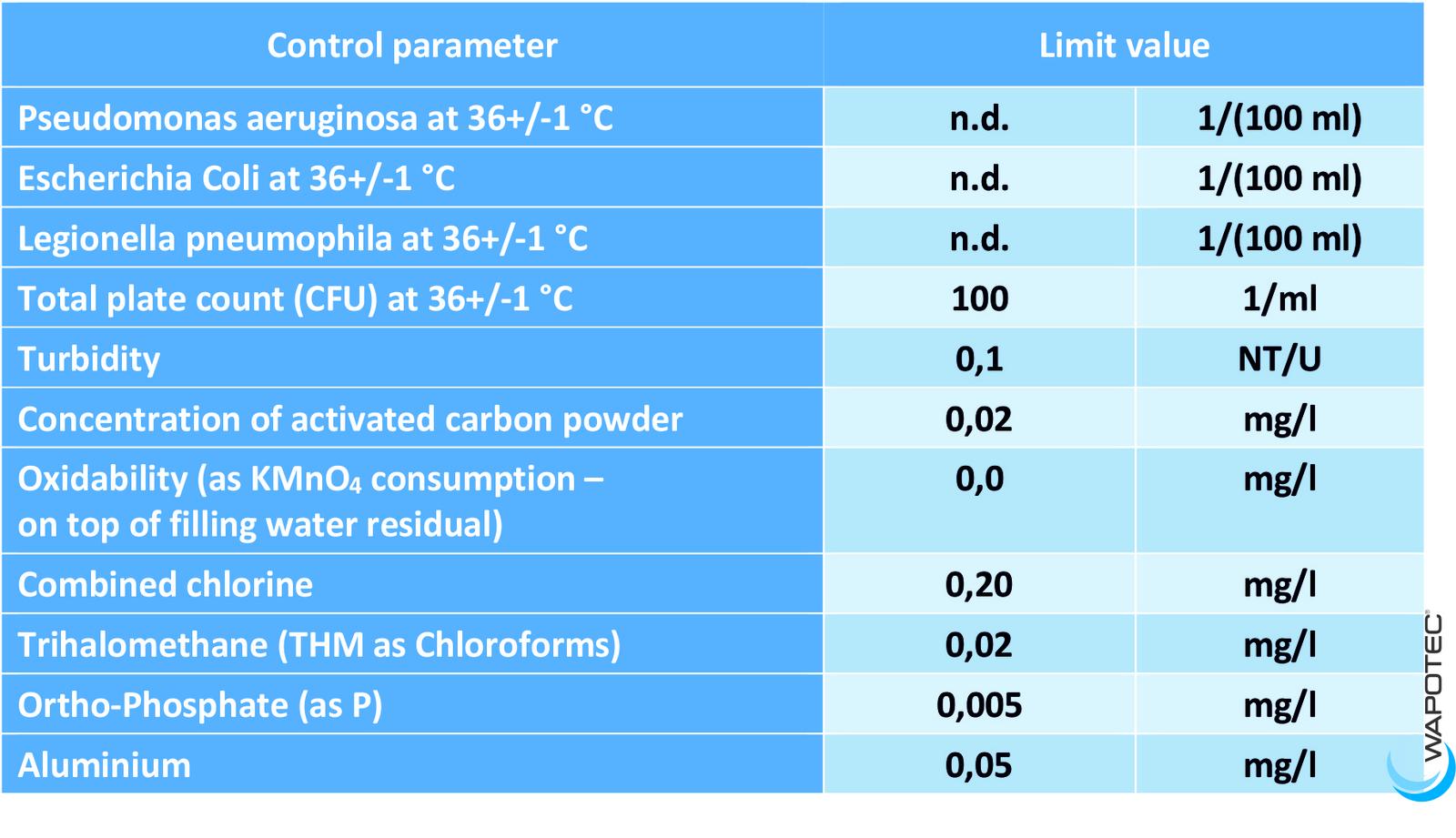

The standards DIN19643/part 2ff offer bench marks to evaluate potential risk through testing certain hygiene parameters (see filter function test). The suggested solution is based on backwash water with a high concentration of disinfectants. However, traditional procedures only achieve short-term improvements because the biofilm is not completely removed.

In pool water treatment systems, the contaminants are mostly comprised of

- oleophilic residues with body fat,

- bather waste,

- flocked residues from ineffective flocculation and filter design as well as

- microorganisms in planktonic and agglomerated form

These cover filter media, pipes, heat exchanges and other surfaces, particularly in areas between the balance tank and post-filtration chlorination dosage points. Coarse filter media such as granulated activated carbon (GAC) offer enormous surfaces where substantial deposits can build up.

The DIN standard 19643-2 highlights requirements and specifies quality criteria of the effluent water quality from filters (filtrate) and sets a high standard in terms of chemical and microbiological limits. This is critical to keep pool and spas open but challenges operators and benefits bather comfort. Some of the limit values include

If any of these limits are exceeded, action must be taken immediately and seriously. WAPOTEC® is offering 2 unique application technologies to apply products, i.e. the DesoPur® fluid and the DesoPur® clean technology. Both are using the WAPO®TEC Rinse Mobile. Patents are granted to protect the know-how in many countries around the globe.

DesoPur® fluid process

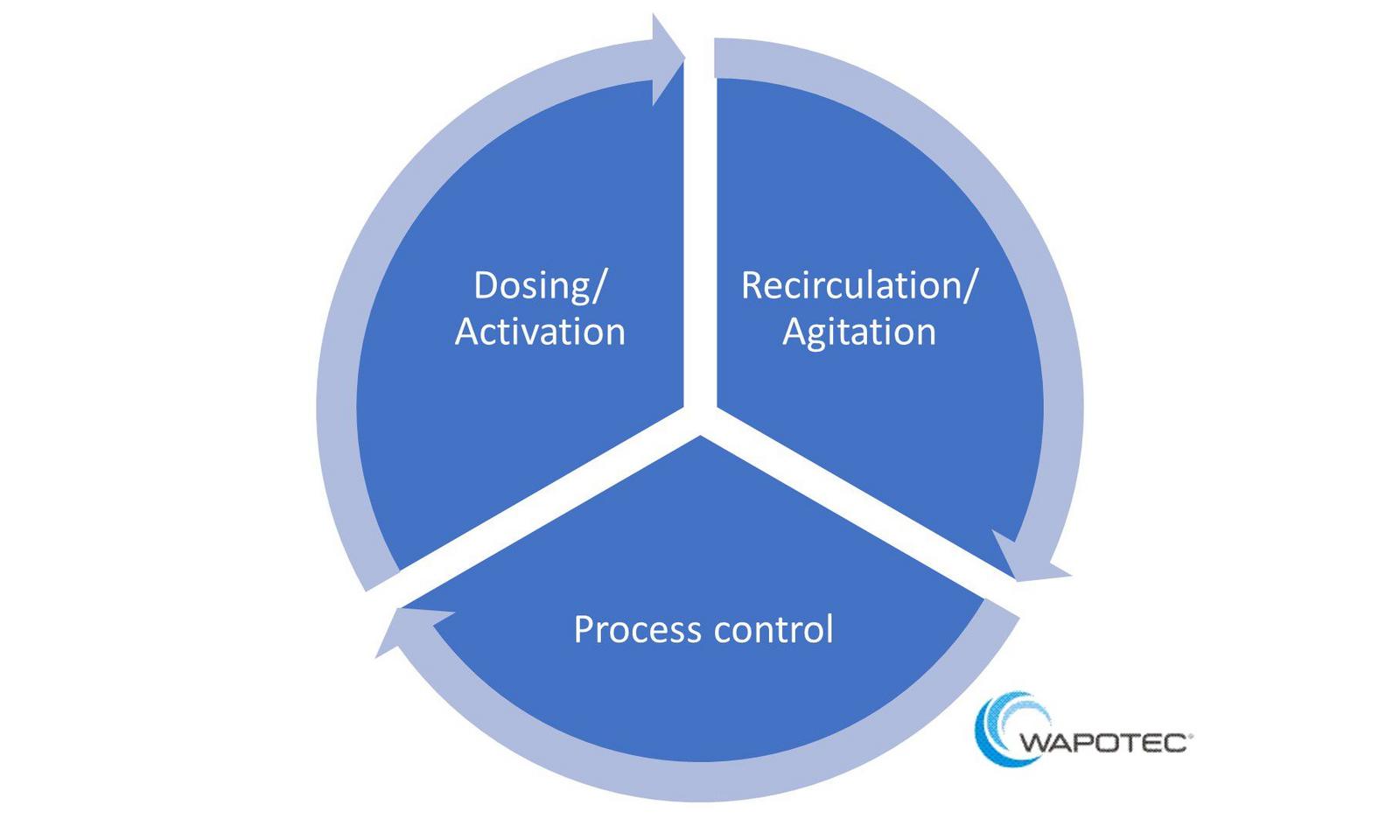

This unique technique allows dosing/activation, recirculation/agitation and process control, all through the use of our multi-purpose WAPO®TEC Rinse mobile.

The WAPO®TEC Rinse Mobile is a versatile service unit for various applications in plant hygiene. The unit is simple to use, compact, light-weight and robust to be shipped from site to site.

Various chemicals can be used to best implement the Sinner circle factors in single or multi-stage process combinations depending on the contaminants suspected … and results can be sampled or measured in-line for perfect control of the progress achieved. Much of the application know-how is protected by various patents and available to our distribution partners when using WAPOTEC® products.

Regeneration of activated carbon

Most operators - perhaps you too - would use chlorine in that case. But chlorinated water (ie. 10 – 200 mg/l free chlorine) leads only to short-term results. Why? The chlorine concentration and exposure time is not efficient enough to get rid of organic contaminations AND microorganisms.

The DesoPur® process was initially developed to regenerate activated granulated carbon (GAC) and other carbon based filter media used for removal of ozone as these filters are typically heavily affected by body fat from patrons, which are coating media and making them incapable of neutralizing ozone and avoiding ozone break-through into the pool. It is applied to control the bacteriological and chemical contamination in the „problem zones“ of the commercial/municipal pool. Numerous applications are internationally patent protected.

The DesoPur® process is quick and easy to apply and saves expensive media replacement cost (including disposal) as well as the down-time resulting from the intervention.

WAPOTEC® has developed innovative maintenance programs for filter media cleaning using the unique DesoPur® product. Both DesoPur® application technologies use the all-in-one dosing and circulation unit that enables a single person to perform the necessary action. This oxididative cleaning and disinfection process should be applied on sand and carbon based media frequently!

To ensure effective performance your filter media should be regenerated regularly (as part of an annual preventative maintenance program) or at least when the filter shows an increased degree of contamination. The efficacy was proven through lab tests carried out by independent laboratories. The DesoPur® treatment process demonstrated to be capable of eliminating deposits and regenerating carbon based filter media inside the filter tank. Microbiological contamination of the pool water from the filter was therefore successfully eliminated in public and commercial pools.

DesoPur®Clean process can be performed in 8 – 16 hours and is mostly applied in smaller filtration systems and/or with limited access.

The patented DesoPur® Fluid process helps to remove biofilm (incl. Legionella or Pseudomonas) and other deposits in filter tanks, filter media (particularly in carbon‐based absorptive filter media), pipe work, balance tanks and other components of water conduits.

The DesoPur® Fluid process can be done by connecting the WAPO®TEC Rinse Mobile (mobile unit with flexible pipe connection) on demand temporarily or by connecting the WAPO®TEC Rinse Station permanently with rigid piping. The interval of (re)contamination after an effective cleaning will depend on various factors.

Commercial and industrial filters are cleaned using the DesoPur® Fluid technology, which allows minimizing the product quantities. This system also allows to easy control when all the contamination is oxidized and/or disinfected as any residual loss can be measured.

Ask WAPOTEC for your individual recommendation!

Actually there is no full protection against microbiological contamination. But with proper treatment and proper disinfection through preventative maintenance, there is a good chance to minimize risks!

Cleaning & Remediation of swimming pools against Crypto(sporidium)

Cryptosporidium oocysts are masters of survival due their high resilience to the traditional disinfection agents like chlorine. This is the key problem preventing and fighting crypto outbreaks. Most of the common water treatment methods are ineffective against crypto.

Most operators would tend to use chlorine in that case. But even hyper-chlorinated water (ie. 10 – 200 mg/l free chlorine) leads only to short-term results. Why? The chlorine concentration and exposure time is not effective enough to get rid of organic contaminations AND microorganisms.

Research has identified chlorine dioxide as an effective Cryptosporidium disinfectant agent. This research suggests that CT value as low as CT78 (exposure to 1.3 mgl of chlorine dioxide for 1 hour, or 0,25 mg/l of chlorine dioxide for 6 hours) will result in inactivation of >90% at normal swimming pool temperatures and pH levels.

Performed at adequate time intervals, LegioCid® Pro technology helps to prevent build-up and maintain performance of your filter media. This innovative process contributes to reduce microorganisms like Legionella, Pseudomonas, Crypto by oxidation and

- helps to control the bacteriological and minimizes chemical contamination

- inactivates Organic substances significantly

- is easy to use and secure.

The basis for safe bathing is thus established.

But our approach goes even further: WAPOTEC has been involved in remediation of contaminated filter systems, swimming pools and spas for more than 25 years by helping operators to respond to incidents. In order to respond to customer needs WAPOTEC has developed customized solutions, consulting services and tools for the prevention and control of water-borne diseases (also called recreational water illnesses):

- Operation is continued at the same level as set up (no shock treatment)

- No slug dosing is required

- Less bather discomfort and impact on air quality is observed

- Exact prediction and reduction of overall pool closure time is achieved

The WAPOTEC method consists of 6 strategies against crypto which is easy to implement in many types of facilities:

- Use Crypto Stress Test to evaluate your crypto exposure risk and the performance of your system.

- Analyze the improvement potential with SKU [Crypto] Evaluator®.

- Maintain proper data logs and maintenance reports with the online tool mypoollog.com (APP).

- Install control procedures and get warned in cased of crypto releases with AQUS® Monitor.

- Implement WAPOTEC®SYSTEM to improve your treatment system and make it crypto fit.

We can help you apply a customized strategy for solid fecal and vomitus incidents as well.

Cleaning & Remediation of Whirlpools & SPA

Never trivialize Legionella problems! Legionella pneumophila are pathogenic bacteria, introduced by bathers, filling water and the airjets. Due to high temperatures, aeration through jets, the relative small volume of water and the introduction of sweat and other organic substances by bathers, offer microorganisms like pseudomonas and legionellae bacteria ideal proliferation conditions.

WAPOTEC® therefore developed a special process for heavily stressed facilities that dissolves biofilm and thereby reduces recontamination. LegioCid®Plus is a precursor-based process registered under the EU biocide legislation and is used for thorough deep cleaning of whirlpools to improve hygiene (as an in-situ biocidal product).

- Cleaning of pipelines, filters and heat exchangers

- Removal of organic deposits throughout the system

- Easy to use

- Emptying via the waste water is unproblematic using our neutralization process

- Deep cleaning of the entire system

Within a few hours or even better overnight filters and heat exchangers (upon owner request), the pool water itself, the basin surface and the entire treatment system including jets can be thoroughly cleaned and disinfected. Deposit, created by (pathogenic) microorganisms will be severely hampered and removed completely. This minimizes further build-up and thus, the basis for safe bathing is established.

The LegioCid®Plus Package offers a simple and complete application with dedicated products. The complete method also includes simple neutralization after treatment and thereby prevents residue from entering the environment and sewer systems. This corresponds with the WAPOTEC® group’s environmental consciousness.

For big commercial and institutional installations, the LegioCid®PRO solution may be chosen.